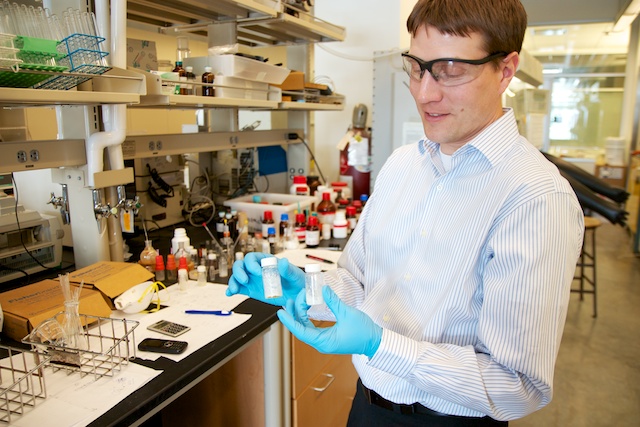

Manufacturing medicines can be expensive and create a lot of waste. Levi Stanley, an expert in the field of catalytic chemistry, wants to make pharmaceutical practices a little more green.

Stanley, an assistant professor of chemistry, is working toward making pharmaceutical reactions more sustainable by creating a catalyst — a material that facilitates chemical reactions — that can be recycled. In addition, his catalyst can facilitate reactions in water, which in contrast to traditional solvents is both inexpensive and recyclable.

"It’s a really nice way to hit two of the big tenets of green chemistry," Stanley said. "We’re making a new catalytic species that can be recycled over and over but also eliminating waste of organic solvents that are commonly used in the reactions."

To create a sustainable catalyst, Stanley needed Wenyu Huang, assistant professor of chemistry, to build a framework for the catalysts. This microscopic, metal and organic scaffolding holds the catalyst out of solution, allowing it to be recovered and reused 10 or more times.

"When you run reactions on a ton scale, and you’re using a precious metal catalyst, we’re talking about significant expense in the catalyst, so certainly industry is looking for ways to minimize that expense," Stanley said.

With the scaffolding holding the catalyst out of solution, Stanley’s focus turned to using this catalyst for a reaction in water instead of a traditional, organic solvent.

Water acts as a transport rather than a traditional solvent, so only a very small number of the chemical ingredients go into the solvent to interact with the catalyst. When a reaction is complete, the water is safe to go down the drain. In contrast, an organic solvent creates 80 percent of a typical reaction’s waste and needs to be incinerated after use.

"You’re left with water that is not completely pure water, but given all the technology in water purification, there’s really innocuous byproducts in it," Stanley said.

To date, Stanley’s new approach has successfully worked for at least one reaction in water. The project is still in early stages, but its potential advancements for the pharmaceutical industry could be great.

“Removing organic solvents from the picture would eliminate a massive amount of the current waste generated by the pharmaceutical industry, much of which is toxic and expensive to deal with,” Stanley said. “We are also likely to find new reactivity as we search for alternative solvents, as we did in our work, that may expand the toolbox of reactions that chemists often use.”